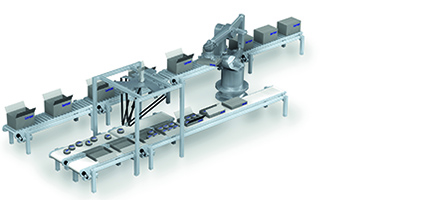

Lenze, a global manufacturer of electrical and mechanical drives, motion control and automation technology, is committed to helping the packaging industry meet demand for integrated automation and robotics motor drive solutions. Designed to simplify control automation in modern packaging line operations, Lenze drive solutions serve a range of applications, including conveyor belts, pick-and-place robots, forming, box erectors, side- and top-loader filling and sealing machinery, and carton palletizing.

“Lenze brings over six decades of experience developing innovative motor drive solutions for packaging,” states Doug Burns, director of business development, Lenze. “Customers know they can trust our high-performing, economical solutions to deliver precision control from the drive shaft to the control system to advanced visualization systems.“

Today’s machine builders for packaging operations are on the forefront of automation. Bottom-line machine costs come down to the drive shaft, gearing and motor, inverter or servo drive. Robots are increasingly common in the packaging industry, which creates additional challenges to integrate the control system or individual kinematics into the automation system. Lenze modular automation systems for centralized controller-based and decentralized drive-based platforms utilize EtherCAT, PLCopen and other industry standards to simplify machine integration into packaging automation topologies. Featuring a practical engineering approach, Lenze guides customers in the design, selection of components and implementation of a packaging machine or automation architecture.

LEARN MORE!